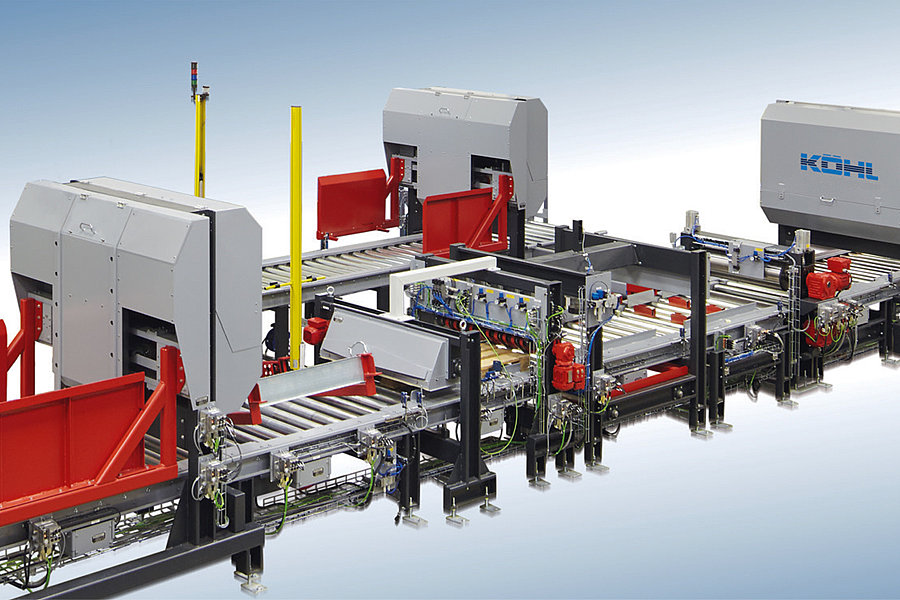

Empty pallet checking system

Automatic inspection of up to 240 pallets per hour

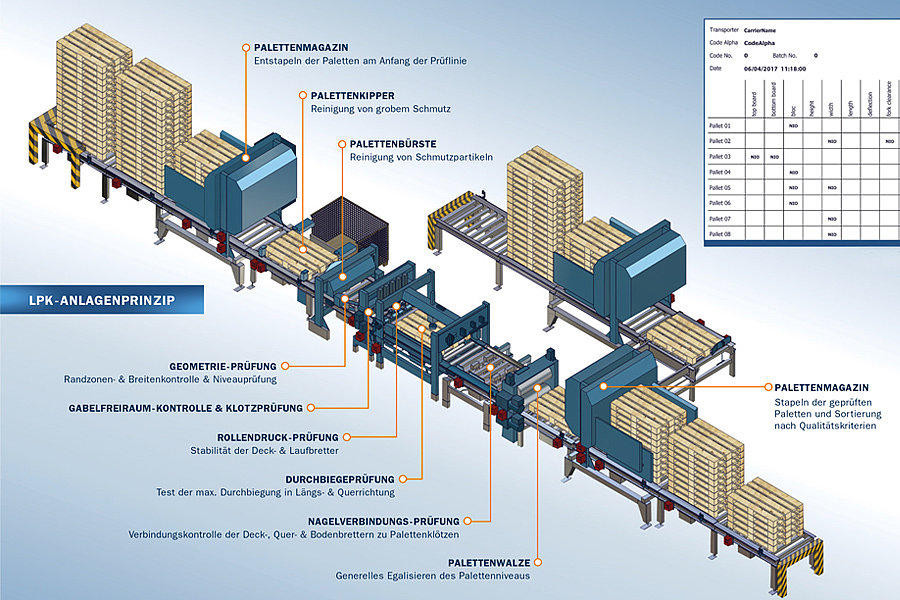

The empty pallet checking system (LPK) developed by KÖHL ensures that only defect-free pallets enter the material flow of palletizing and transport systems, high-bay warehouses and storage and retrieval machines (SRMs). The modular system comprises several inspection stations that check the pallets for dimensional accuracy and stability. The pallets are cleaned, their geometry and fork clearance are checked, stability and deflection are measured and the nail joints are checked. The pallet level is also equalized. Intact pallets are sorted according to defined quality criteria and stacked in the pallet magazine. The system uses modern control and visualization technology, which informs the operator about the test results at all times.

Features

- Modular design:

Flexible use of the modules, which can be individually adapted to customer-specific requirements. - Standalone or integrated:

The system can be supplied as a standalone solution or seamlessly integrated into existing systems. - Customizable conveyor technology & layout:

Conveyor technology and system layout can be flexibly adapted to the customer's circumstances and needs. - User-friendly design:

Durable design with simple operation for daily use. - Modern visualization:

User-friendly visualization for easy operation and analysis of the system in real time. - Creation of test reports:

Automatic generation of test reports that can be exchanged digitally with higher-level systems. - Easy maintenance:

Maintenance-friendly design to minimize downtime and maximize availability.

Downloads

Related Products

Any Questions?

We're happy to help

Whether you need advice, technical details, or a custom solution: Our team is here for you!

Feel free to get in touch – we look forward to hearing from you.